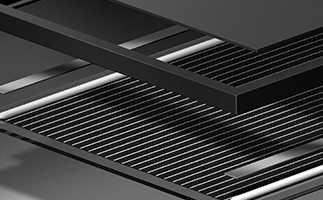

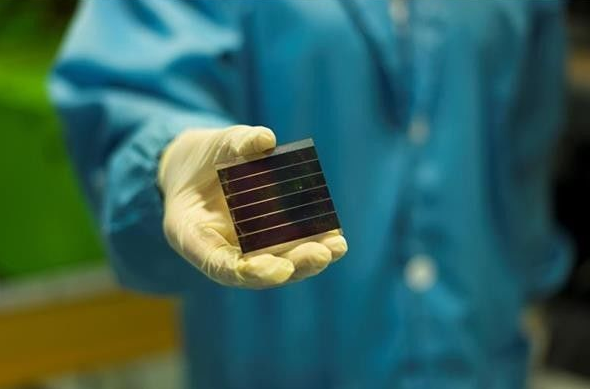

意大利科学家使用氧化钛海绵成功防止半透明太阳能电池中的铅泄漏,器件显示出与半透明钙钛矿器件相当的效率,平均可见光透光率(AVT)为31.4%。

图片:CNR-IMM

意大利微电子和微系统研究所(CNR-IMM)的科学家开发了一种半透明的钙钛矿太阳能电池。他们通过在器件上沉积氧化钛(TiO2)海绵来防止潜在的铅(Pb)泄漏。

“我们设想太阳能电池用于建筑集成光伏(BIPV)和农业光伏的应用,其中潜在的铅泄漏可被视为严重的公共环境和健康风险来源,”研究员Salvatore Valastro告诉PV杂志。

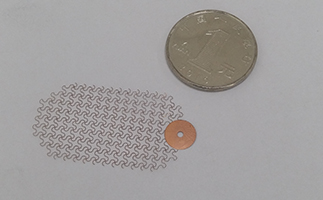

TiO2是一种高度吸附的材料,在钙钛矿太阳能电池中充当有效的电子传输层(ETL)。为了解决潜在的铅(Pb)泄漏问题,研究人员制备一种无溶剂的多孔TiO2薄膜,形成了一种海绵状结构,能够在模拟灾难性事件期间从受损器件中捕获Pb。

“TiO2海绵可以吸收浓度范围为24 g/cm2至63 g/cm2的铅,其相当于厚度为200 nm(半透明PSC)至500 nm(不透明PSC)的MAPbI3,”研究人员解释说。

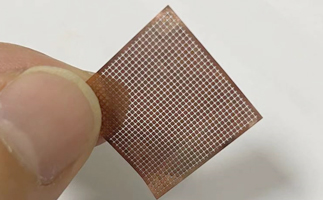

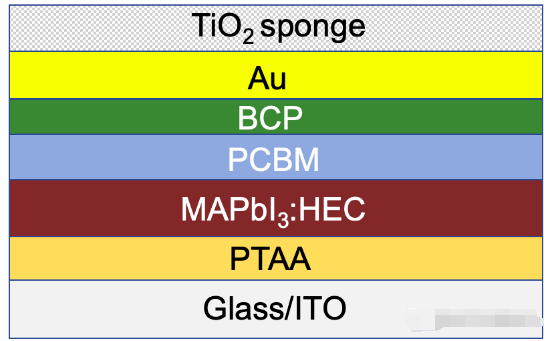

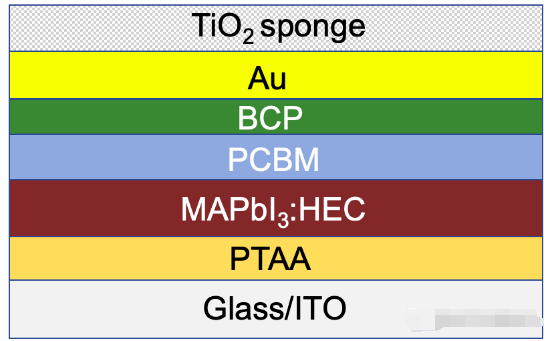

他们用玻璃和氧化铟锡(ITO)做基板,由聚三芳胺(PTAA)制成空穴传输层(HTL),带有TiO2海绵的钙钛矿吸收体,由苯基-C61-丁酸甲酯(PCBM)制成的电子受体,浴库普林(BCP)缓冲层,金(Au)金属电极构建电池。

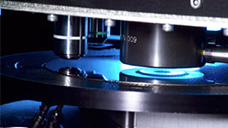

“我们通过使用溅射设备无溶剂沉积TiO2海绵,这是一种易于扩展的沉积方法,被半导体制造公司广泛使用,”Valastro说。“在沉积过程之前执行1分钟的预溅射步骤,以清理钛靶的表面以去除氧化层。”

太阳能电池实现了11.6%的转换效率,平均可见光透光率(AVT)为31.4%。“11.6%的效率是这种半透明架构的典型特征,”Valastro说。

研究小组在“Preventing lead leakage in perovskite solar cells with a sustainable titanium dioxide sponge,”中描述了这种电池技术,该研究最近发表在《自然可持续性》上。

“我们的方法代表了解决BIPV,BAPV,农业光伏和不透明设备的铅释放的具体步骤,也为报废设备中的铅回收铺平了道路,”该团队总结道。

(消息来源:pv-magazine.com)

Semitransparent perovskite solar cell with 11.6% efficiency

Italian scientists have used a titanium oxide sponge to successfully prevent lead leakage in a semitransparent solar cell. The device has demonstrated comparable efficiency to semi-transparent perovskite devices and has an average visible transmittance (AVT) of 31.4%.

Scientists from the Italian Institute for Microelectronics and Microsystems (CNR-IMM) have developed a semi-transparent perovskite solar cell. They achieved this by depositing a titanium oxide (TiO2) sponge on the device to prevent potential lead (Pb) leakage.

“We conceived the solar cell for applications in building-integrated photovoltaics (BIPV) and agrivoltaics, where the potential lead leakage can be viewed as a serious public environmental and health risk source,” researcher Salvatore Valastro toldpv magazine.

TiO2, a highly adsorbent material, serves as an effective electron transport layer (ETL) in perovskite solar cells. To address potential lead (Pb) leakage, the researchers created a solvent-free porous TiO2 film, forming a sponge-like structure capable of capturing Pb from damaged cells during simulated catastrophic events.

“The TiO2 sponge can sequester Pb in concentrations ranging from 24 g cm2 to 63 g cm2, which are equivalently contained in MAPbI3 layers with thicknesses from 200 nm (semi-transparent PSC) to 500 nm (opaque PSC),” the researchers explained.

They built the cell with a substrate made of glass and indium tin oxide (ITO), a hole transport layer (HTL) made ofpoly-triarylamine (PTAA), a perovskite absorber with the TIO2 sponge, an electron acceptor made of phenyl-C61-butyric acid methyl ester (PCBM), a bathocuproine (BCP) buffer layer, a gold (Au) metal contact, and the TIO2 sponge.

“We deposited the sponge via a physical solvent-free deposition, by using sputtering equipment, an easily up-scalable deposition method, which is widely used by semiconductors manufacturing companies,” Valastro said. “A pre-sputtering step of 1 min is performed before the deposition process to clean up the surface of the titanium target to remove oxidized layers.”

The solar cell achieved a power conversion efficiency of 11.6% and has an average visible transmittance (AVT) of 31.4%. “The efficiency value of 11.6% is characteristic of this semi-transparent architecture,” said Valastro.

The research team described the cell tech in “Preventing lead leakage in perovskite solar cells with a sustainable titanium dioxide sponge,” which was recently published in Nature Sustainability.

“Our method represents a concrete step forward in addressing Pb release for BIPV, BAPV, agrivoltaics and opaque devices, and also paves the way for Pb recycling in end-of-life devices,” the team concluded.

本站所发表内容转载时会注明来源,版权归原出处所有(无法查证版权的或未注明出处的均来源于网络搜集)。转载内容(视频、文章、广告等)只以信息传播为目的,仅供参考,不代表本公众号认同其观点和立场。内容的真实性、准确性和合法性由原作者负责。如涉及侵权,请联系删除,此转载不作为商业用途。